Fiber vs. CO2 vs. UV: Which laser marker should I choose?

Lasers can mark and process a wide variety of products, but there's no one-size-fits-all answer for every application. Fiber, CO2 and UV laser markers perform differently depending on the application and material.

Here's a brief overview of Fiber, CO2 and UV laser technology. We've also included some sample marking videos that highlight the strengths and weaknesses of each system.

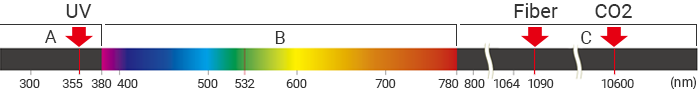

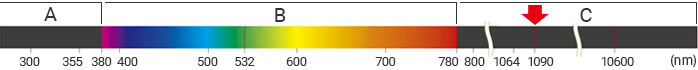

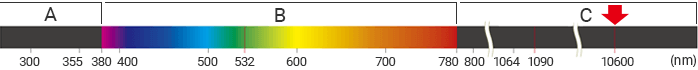

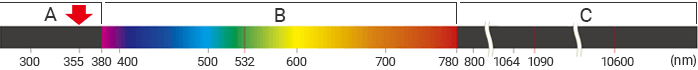

The most important difference between Fiber, CO2 and UV laser markers is the wavelength of light they produce.

Short wavelengths typically have more energy and a higher absorption rate than long wavelengths. As a result, a laser's wavelength affects its ability to mark certain materials.

The features of and marking examples for the different wavelength types are introduced below.

Fiber lasers have a 1090 nm wavelength, making them IR (infrared) lasers. Fiber lasers can mark a wide range of materials, though they are optimized for metal marking applications. Their high power makes them perfect for annealing and engraving applications, but they cannot mark transparent objects since IR light passes straight through.

A Ultraviolet range B Visible range C Infrared range

CO2 lasers have 10x the wavelength of standard wavelength systems. They're great at marking paper, resins, wood, rubber and transparent materials (like

glass and PET). However, it's nearly impossible to mark metal with a CO2 laser marker because the laser light is not absorbed.

Results

Results

CO2 Laser: CO2 laser light creates non-contrast marks and causes the resin's surface to swell.

UV Laser: UV laser light reacts with the pigments in the resin to produce high-contrast, damage-free marks.

CO2 Laser: CO2 laser light burns the surface of the carton to produce marks.

UV Laser: The paper on the carton absorbs UV laser light, resulting in high-contrast marks.

CO2 Laser: CO2 light uses heat to produce marks.

UV Laser: Marking isn't possible because clear plastic doesn't absorb enough UV laser light.

CO2 Laser: CO2 laser light creates marks by burning off the pouch's surface.

UV Laser: UV laser light reacts with the film on top of the pouch to produce high-contrast, damage-free marks.

Fiber lasers can quickly mark the widest range of materials and typically produce the most contrast on metals. However, fiber lasers cannot mark transparent materials and will sometimes damage the marking surface.

UV lasers provide the most contrast on resins. UV lasers have the added benefit of creating damage-free marks.

CO2 lasers burn the target with heat, making them ideal for marking wood, paper, ceramic and transparent targets.